In the world of manufacturing and production, efficiency and precision are paramount. One of the key components that contribute to these factors is the use of industrial filling machines. These machines are integral to various industries, ensuring that products are filled accurately and consistently, which is crucial for maintaining quality and meeting consumer demands. From food and beverages to pharmaceuticals and cosmetics, filling machines play a vital role in the production process. This article delves into the workings of industrial filling machines, exploring their applications across different sectors and highlighting their importance in modern manufacturing.

How Industrial Filling Machines Work

Industrial filling machines are designed to automate the process of filling containers with a specific quantity of product. The operation of these machines can vary depending on the type of product being filled, the container used, and the desired speed and accuracy of the filling process. Generally, filling machines operate using one of several methods, including volumetric, gravimetric, and flow meter-based systems.

Volumetric filling machines measure the volume of the product to be dispensed, ensuring that each container receives the exact amount required. This method is particularly useful for products that are consistent in density and viscosity, such as liquids and creams. Gravimetric filling machines, on the other hand, use weight to determine the amount of product to be filled. This method is ideal for products that may vary in density, as it ensures that each container receives the correct weight of product.

Flow meter-based systems are another common type of filling machine. These machines use flow meters to measure the flow rate of the product, allowing for precise control over the amount dispensed. This method is often used for high-speed filling applications, where accuracy and speed are both critical.

For more detailed information on the different types of filling machines and their specific applications, you can visit https://stm-pack.com/machines-categories/filling-machines/.

Applications of Filling Machines in Production

Filling machines are utilized in a wide range of industries, each with its own unique requirements and challenges. In the food and beverage industry, filling machines are essential for bottling liquids such as water, juices, and soft drinks. These machines ensure that each bottle is filled to the correct level, maintaining consistency and quality across the production line.

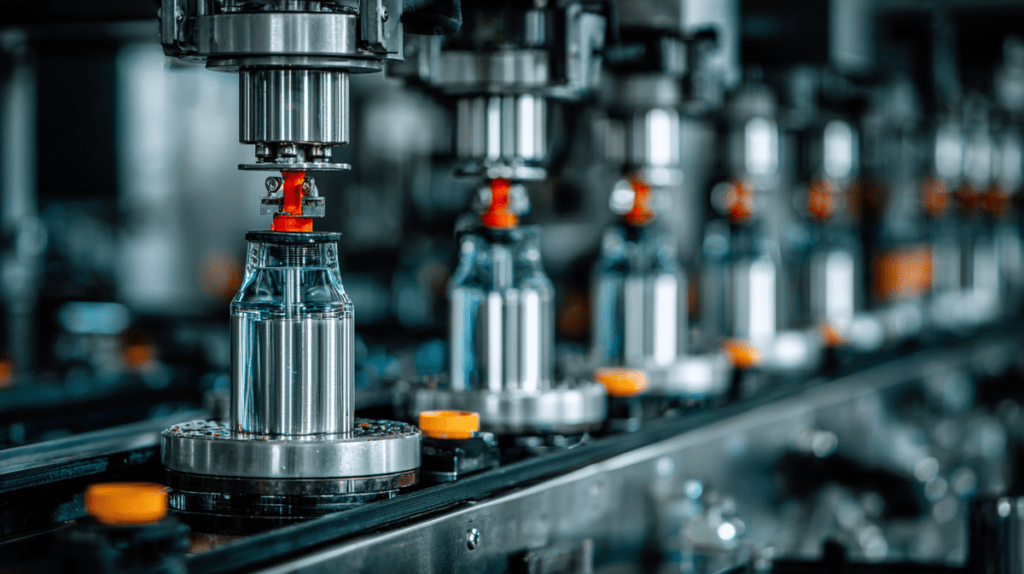

In the pharmaceutical industry, filling machines are used to fill vials, ampoules, and syringes with medications. Precision is crucial in this sector, as even the slightest deviation in dosage can have significant consequences. Filling machines in this industry are often equipped with advanced features such as sterile environments and automated cleaning systems to ensure the highest standards of hygiene and accuracy.

The cosmetics industry also relies heavily on filling machines to package products such as lotions, creams, and perfumes. These machines must be capable of handling a variety of container shapes and sizes, as well as different product viscosities. The ability to quickly switch between different product lines is a valuable feature in this fast-paced industry.

For a comprehensive look at how filling machines are integrated into complete production lines, particularly in bottling applications, you can explore https://stm-pack.com/filling-lines-categories/complete-filling-lines/bottling-lines/.

The Importance of Filling Machines in Modern Manufacturing

Filling machines are a cornerstone of modern manufacturing, providing numerous benefits that enhance production efficiency and product quality. By automating the filling process, these machines reduce the need for manual labor, minimizing the risk of human error and increasing the speed of production. This automation also allows for greater consistency in product filling, ensuring that each container meets the required specifications.

Moreover, filling machines contribute to cost savings by reducing waste and optimizing the use of raw materials. Precise filling ensures that no product is wasted, and the ability to quickly adjust machine settings allows manufacturers to respond to changes in production demands without significant downtime.

In addition to these practical benefits, filling machines also play a role in enhancing workplace safety. By automating potentially hazardous tasks, these machines help to protect workers from exposure to harmful substances and reduce the risk of workplace accidents.

Overall, the integration of filling machines into production lines is a testament to the advancements in manufacturing technology. As industries continue to evolve, the demand for efficient and reliable filling solutions will only increase, making these machines an indispensable part of the production landscape.