Understanding Supply Chain Disruptions

Supply chain disruptions occur when an unplanned event interferes with the production, transport, or delivery of goods and services. These disruptions can stem from various sources like natural disasters, political instability, or economic shifts, each bringing its specific challenges.

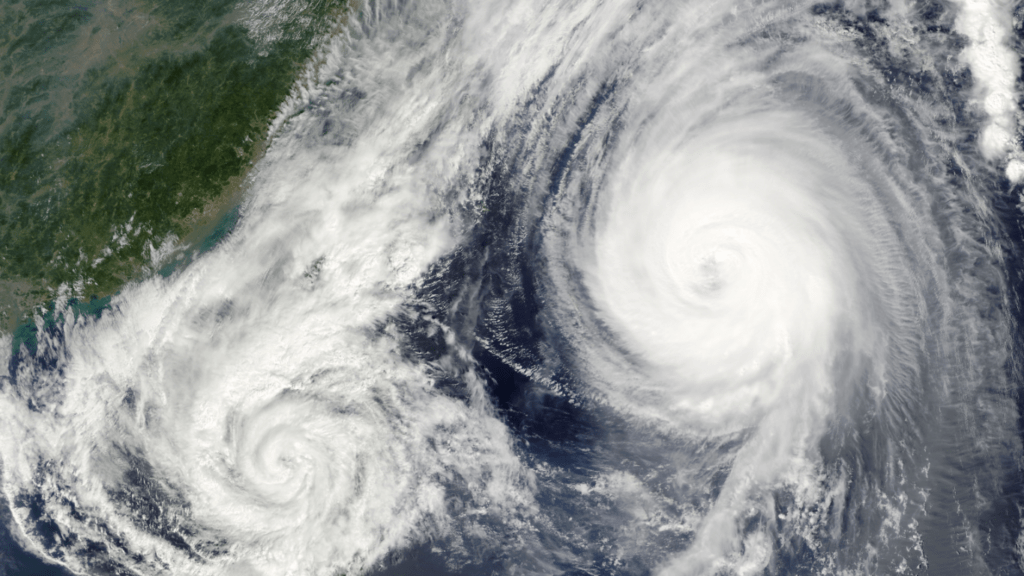

- Natural Disasters

Events like hurricanes, earthquakes, and floods can halt production facilities, damage infrastructure, and delay transport networks. For example, Hurricane Katrina in 2005 disrupted supply chains across many industries, causing significant economic losses.

- Political Instability

Geopolitical tensions, sanctions, and trade wars can create unpredictable environments for businesses. The US-China trade conflict, for instance, led to increased tariffs that affected global trade and supply chains, forcing companies to reconsider their sourcing strategies.

- Economic Shifts

Fluctuations in currency values, market demand, and economic policies can disrupt supply chains. The 2008 financial crisis serves as a prime example, where sudden economic downturns led to reduced consumer spending and disrupted demand planning.

Each disruption category influences supply chains differently, requiring tailored strategies to mitigate risks. Businesses must understand these factors to prepare effectively for potential disruptions.

Common Causes of Disruptions

In my experience, several factors frequently disrupt supply chains, causing significant challenges for businesses. Understanding these causes is vital for mitigating risks.

Natural Disasters

Natural disasters like hurricanes, floods, and earthquakes can severely impact supply chains. In 2011, the Tōhoku earthquake and tsunami in Japan disrupted global supply chains, triggering a significant shortage of automotive parts. Such catastrophes halt production, damage infrastructure, and delay deliveries, creating widespread logistical challenges.

Economic Instability

Economic instability disrupts supply chains by affecting demand and pricing. The 2008 financial crisis serves as a prime example. Many businesses struggled with demand planning due to unpredictable market conditions. Fluctuating currency values and inflation rates further complicate supply chain operations, leading to increased costs and inventory challenges.

Political Turbulence

Political turbulence often results in regulatory changes, trade embargoes, and increased tariffs. For instance, the US-China trade conflict led to heightened tariffs, affecting companies relying on cross-border trade. This kind of instability poses risks to production timelines, costs, and market access, making strategic adjustments essential.

Technological Failures

Technological failures disrupt supply chains by causing delays and increasing vulnerability to cyber-attacks. In 2017, the NotPetya cyber-attack significantly impacted companies worldwide, including shipping giant Maersk, which faced millions in losses. Such failures compromise system integrity, leading to operational disruptions and financial losses.

Understanding these common causes of disruptions helps in implementing targeted strategies to ensure supply chain resilience.

Impacts of Supply Chain Disruptions

Supply chain disruptions can have far-reaching impacts on various aspects of a business. It’s important to understand these impacts to develop strategies to mitigate them.

Financial Losses

Supply chain disruptions often result in significant financial losses. Delays in production and delivery can lead to increased costs and lost revenue. For instance, when natural disasters like hurricanes strike, companies might face damaged infrastructure and halted operations, leading to expensive recovery efforts. During the 2011 Tōhoku earthquake and tsunami, many businesses experienced massive financial hits due to extended production shutdowns.

Operational Delays

Operational delays are another major impact of supply chain disruptions. When political instability or regulatory changes occur, they can cause significant delays in the production timeline. For example, the US-China trade conflict has led to increased tariffs and additional regulatory requirements, which have considerably slowed down supply chain processes. These delays can affect everything from raw material procurement to final product delivery.

Customer Dissatisfaction

Customer dissatisfaction often follows operational delays and unmet delivery promises. When products are delayed or unavailable, customers lose trust and may turn to competitors. For instance, during the NotPetya cyber-attack, multiple companies faced disruptions in their supply chain operations, leading to misses in delivery deadlines and lowered customer satisfaction levels. Maintaining a smooth and reliable supply chain is crucial for upholding customer trust and loyalty.

Strategies for Mitigating Disruptions

Navigating supply chain disruptions requires proactive strategies. I’ll explore key approaches that ensure business continuity and resilience.

Risk Assessment and Management

Recognizing potential risks and managing them preemptively can save a company from severe disruptions. For effective risk assessment, businesses should first map out their entire supply chain, from raw materials to final delivery. By identifying vulnerable points, companies can develop contingency plans. Tools like risk matrices help prioritize risks based on their likelihood and impact. A robust risk management plan includes regular reviews and updates to stay relevant amidst changing circumstances.

Diversifying Supply Sources

Relying on a single supplier increases vulnerability. Diversifying supply sources mitigates this risk and ensures an uninterrupted supply of critical materials. Engage with multiple suppliers from different geographic locations. This practice reduces exposure to regional disruptions like natural disasters or political instability. Strategic partnerships with global and local suppliers help maintain flexibility and cushion against supply chain shocks.

Leveraging Technology

Advanced technology streamlines supply chain processes and enhances visibility. Implementing systems like IoT (Internet of Things) provides real-time tracking of shipments and inventory levels. AI (Artificial Intelligence) can predict potential disruptions by analyzing patterns and trends. Blockchain technology offers traceability, ensuring authenticity and transparency throughout the supply chain. Investing in these technologies results in informed decision-making and quicker response times.

Strengthening Supplier Relationships

Building strong relationships with suppliers is vital for resilience. Regular communication fosters trust and collaboration, essential during disruptions. Businesses should work closely with suppliers to understand their challenges and offer support. Joint risk management initiatives, such as shared contingency plans, enhance preparedness. Long-term partnerships with clear expectations and mutual benefits contribute to a stable and reliable supply chain network.

Case Studies of Supply Chain Resilience

Examining real-world examples of supply chain resilience offers valuable insights into best practices and strategies for handling disruptions.

Success Stories

Several companies have demonstrated exceptional supply chain resilience:

- Toyota: After the 2011 earthquake in Japan, Toyota faced significant disruptions. They quickly adapted by implementing a supply chain risk management system. This system allowed them to identify alternative suppliers and streamline their processes, reducing production downtime and mitigating losses.

- Cisco: During the 2011 Thailand floods, Cisco’s supply chain was at risk. By leveraging their global network of suppliers and robust inventory management system, Cisco could shift production to unaffected areas. This proactive approach minimized the impact on their operations.

- Procter & Gamble: When Hurricane Maria hit Puerto Rico in 2017, P&G’s operations were disrupted. However, their pre-established disaster recovery plans, including diversified suppliers and alternative logistics strategies, enabled them to maintain supply chain continuity.

Lessons Learned

These success stories provide crucial lessons for enhancing supply chain resilience:

- Risk Management: Toyota’s experience underscores the importance of developing a comprehensive supply chain risk management system. Identifying alternative suppliers and mapping vulnerable points can significantly mitigate disruptions.

- Flexibility: Cisco’s approach highlights the necessity of maintaining flexibility within the supply chain. A global network of suppliers and adaptive inventory management can aid in redistributing production during crises.

- Preparedness: P&G’s proactive disaster recovery plans exemplify the value of preparedness. Diversifying suppliers and having alternative logistics strategies can ensure continuity even in the face of severe disruptions.

The Future of Supply Chain Management

Emerging trends and cutting-edge technologies are reshaping the landscape of supply chain management, promising increased efficiency and resilience.

Emerging Technologies

Several technologies are transforming supply chain management. Artificial intelligence (AI) offers predictive analytics, enabling businesses to anticipate disruptions and optimize inventory levels. Companies like Amazon use AI for demand forecasting, ensuring products are available when needed.

The Internet of Things (IoT) enhances real-time tracking across supply chains. Sensors on shipments provide data on location and condition, reducing loss and spoilage. Walmart leverages IoT for monitoring perishable goods, ensuring freshness upon arrival.

Blockchain technology provides transparency and security in supply chain transactions. By creating immutable records, it prevents fraud and enhances trust among stakeholders. IBM uses blockchain to track food safety, from farm to table, ensuring product integrity.

Evolving Best Practices

Supply chain best practices evolve as businesses adopt new strategies. Agile methodologies now dominate, emphasizing flexibility to swiftly adapt to changes. Companies like Zara excel by using agile supply chains to respond rapidly to fashion trends.

Sustainability has become a key focus. Eco-friendly practices, such as reducing emissions and waste, not only benefit the environment but also improve brand loyalty. Patagonia incorporates sustainable materials and ethical manufacturing, setting industry standards.

Risk management is increasingly data-driven. Advanced analytics help identify vulnerabilities and create robust contingency plans. UPS applies data analytics to predict disruptions and reroute shipments efficiently, maintaining delivery schedules even during crises.

By adopting these technologies and evolving best practices, businesses can build more resilient and responsive supply chains, capable of navigating future challenges.